Insert Molding Service

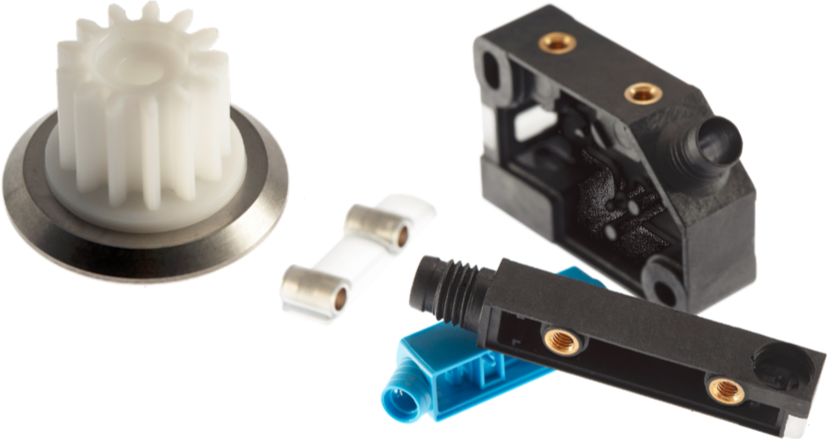

High precision, multi-material insert molded components utilized in a variety of applications

Beyonics specializes in insert molding, a unique manufacturing process that combines metal and molten plastic into a single, high-performance component. This process uses engineering plastics with high fiber or mineral content—up to 60%—to enhance structural integrity, wear resistance, tensile strength, weight reduction, and conductivity, while metallic elements provide added strength. The result is a robust, heterogeneous composite that simplifies complex multi-part assemblies into integrated units, delivering superior functional performance, reliability, and value for mission-critical applications in the MedTech, automotive, and technology industries.

Applications

- MedTech & Healthcare - We produce essential medical devices and components, including diagnostic and consumable devices. ensuring precise functionality and biocompatibility. Our process delivers reliable seals to prevent contamination and ultra-smooth surfaces for easy sterilization.

- Mobility & Automotive - We manufacture durable connectors, sensor housings, and ADAS components. Our components are engineered to withstand extreme temperatures, vibration, and exposure to fluids, supporting the industry’s shift toward electrification and autonomous vehicles.

- SmartTech - We create shielded enclosures, durable connectors, and sensitive sensor bodies for consumer electronics and communication devices.. Insert injection molding improves the structural integrity, functionality, and performance of industrial components. This approach streamlines production, reduces assembly steps, and enhances product reliability.

Why Partner with Beyonics for Insert Molding Services

Choosing our insert molding services translates to tangible advantages for your production line and end product. Reduced Complexity & Cost: Eliminate fasteners and secondary assembly operations, streamlining your supply chain and lowering total cost.

- Enhanced Reliability: Create strong mechanical joints and stable electrical connections that outperform traditionally assembled parts.

- Superior Consistency: Achieve repeatable dimensions, pristine A-surface cosmetics, and consistent quality from the first part to the last.

- Expert Support: Benefit from our vertical integration, with expert guidance from initial design through production and validation. Our team ensures your program moves efficiently from concept to approval.

Our Capabilitie and Materials

We support simple and complex insert molding programs, from micro-connectors to large sensor housings.

- Components: Connectors, sensor bodies, threaded inserts, bushings, and EMI shields.

- Materials: We mold a wide range of engineering-grade resins (ABS, PC, PBT, PPS, PEEK) chosen for strength, thermal stability, and chemical resistance.

- Inserts: Our expertise encompasses a vast array of insert types, including brass and stainless-steel threads, stamped terminals, and custom machined elements.

Our Design for Manufacturing (DFM) Support

A successful insert molding project starts with a well-optimized design. Our engineers provide comprehensive DFM analysis to ensure excellence in production, performance, and cost-effectiveness. We focus on:Incorporate retention features on inserts to resist pullout and rotation ensuring mechanical stability.

- Keep wall sections as uniform as possible near inserts.

Maintain consistent wall thickness near inserts to minimize warping, sink marks, and internal stresses - Use generous radii and draft to reduce sink and stress.

Use rounded corners and appropriate draft angles to reduce stress concentrations and improve mold filling. - Choose gate locations that protect sealing and visible areas.

Selection of gate location and type to protect critical sealing surfaces and visible areas, preserving part functionality and aesthetics. - Match resin and insert materials for thermal and chemical compatibility.

- Simulation-driven design.

- Leverage Moldflow to validate part and mold design, optimizing flow, cooling, and warpage before production.

We review CAD early, propose steel-safe features, and use simulation to guide gating, venting, and cooling before cutting steel.

Process and Quality Control

Our structured, risk-averse process ensures stable cycle times and exceptional quality. This rigorous approach, certified under ISO 9001, ISO 13485, and IATF 16949, includes:

- Feasibility & DFM: Identify potential risk areas early and define target specifications.

- Simulation & Tool Design: Plan optimal balance, gating, and cooling.

- Build & Metrology: Verify electrodes and steel before tryout to ensure precision.

- Trial & Optimization: Functionality, cosmetics, and dimensions for reliable production.

- Validation & Evidence: Produce first-article reports and capability checks to confirm performance.