Plastic Tooling Solutions

Creative design and tooling solutions to support aluminium die casting and plastics injection molding projects

Home » Portfolios » Plastic Tooling

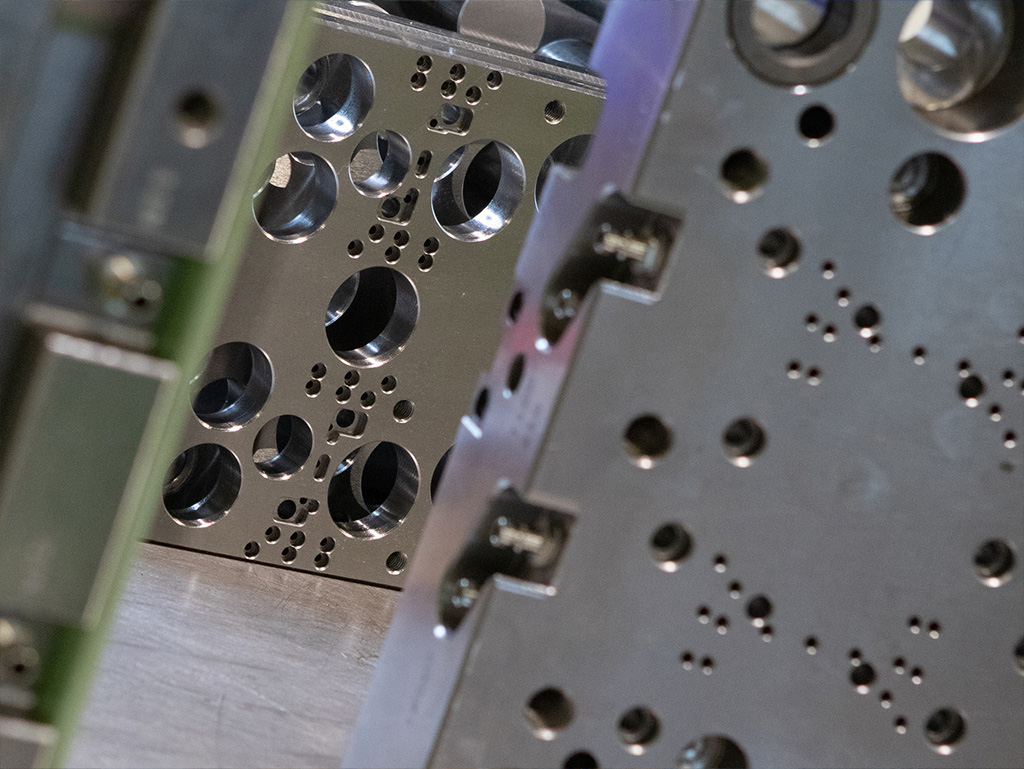

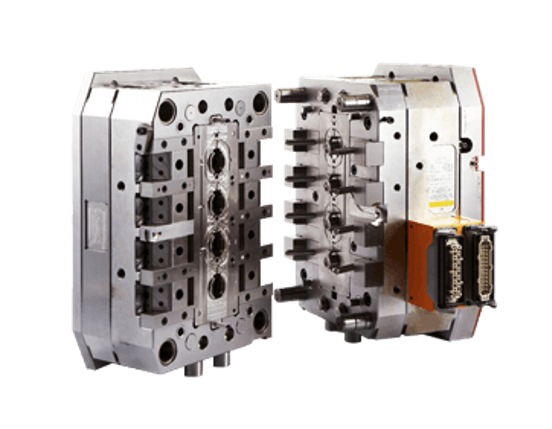

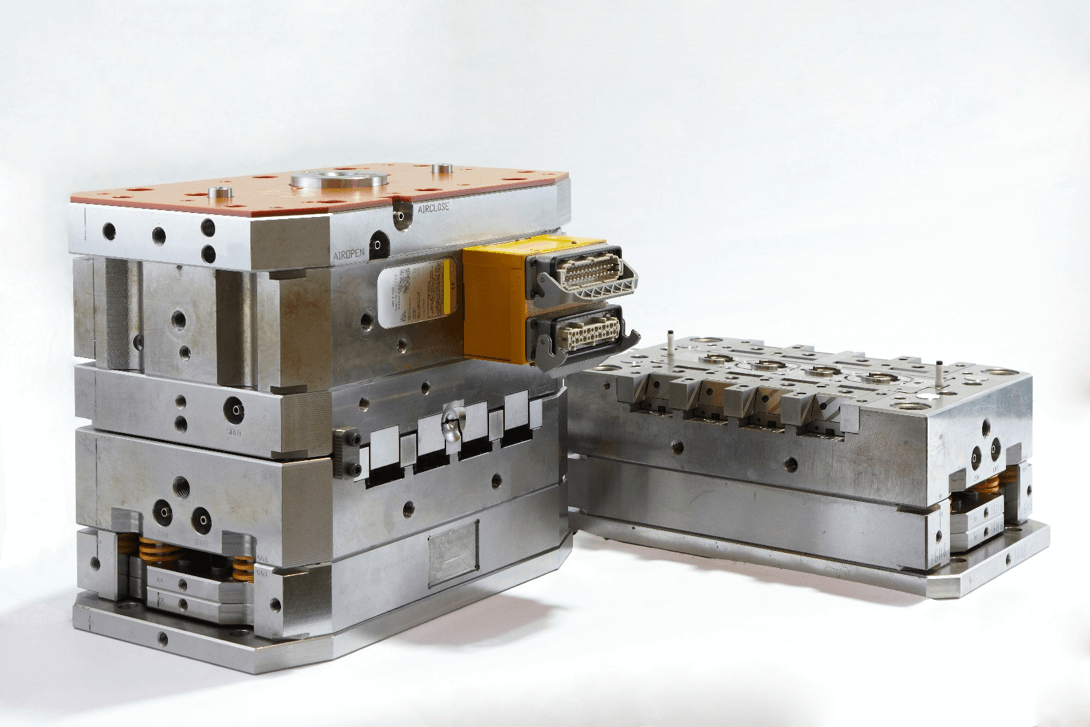

Experienced toolmakers at Beyonics specialize in providing creative tooling solutions to support projects for aluminium die casting and plastics injection molding production processes.

Applications

- Sequential mold, stack mold, double-colour injection mold, insert mold, outsert mold, overmold, unscrew mold, etc.

- Large automotive and medical enclosure and cosmetic tools up to 450 tons clamping force.

- Precision tools and gears up to AGMA 8 (Din 9 or JIS 5).

- Molds for small precision to large parts from 15 to 1600 tons.

- Parts with wall thickness of less than 0.18 mm.

Through a unique combination of engineering, and construction

Engineering

Services

- Design for Manufacturing (DFM)

- Early Involvement

- Mold Flow Analysis

- Customized Automation

Tooling

Technology

- Makino, Charmilles and Sodick wire-cut / CNC machines for precision injection mold fabrication

- Makino / Charmilles EDM machines

- 5-axis milling, grinding and super drill machines

- CMM and Optical Scope in metrology laboratory

- Advanced Unigraphics 3D NX software for mold design and CAM programming

- Autodesk Mold Flow Insight for plastic flow analysis prior to final mold design and fabrication to optimize product manufacturability and quality

Quality

Assurance

- ISO 9001

- ISO 14001

- ISO 13485