Capabilities

Advanced Precision Engineering and Manufacturing Solutions

Our tooling capabilities, knowledge of special materials, R&D Lab, and factory automation create go-to-market designs and fast solutions.

We specialise in the Automotive, Medical and Technology sectors but we are by no means limited to them.

We are always open to new ventures, please feel free to get in touch and let us know your requirements.

Our Capabilities

Industry Case Studies

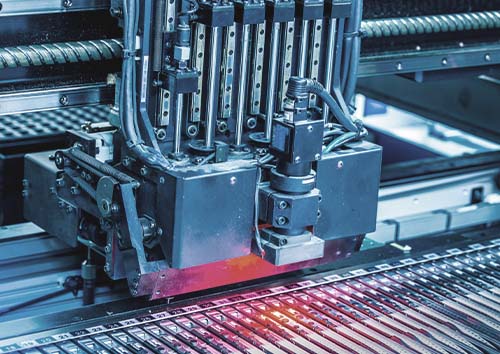

Beyonics provides precision parts and customised interconnect solutions and electronics assembly services to global Tier 1 automotive parts manufacturers.

Specialists at precision-engineered aluminum die-cast, metal stamped, and plastic components.

Complete traceability and robust quality control system.

From design optimization and prototyping to mass production and delivery, we’re with you at every stage, ensuring a smooth journey from start to finish.

Rigorous testing and inspection processes guarantee that your products meet the highest standards.

Product Example

Integrated housing for radar system

Casting + Insert Molding + Powder Coating + Bonding + Gasketing

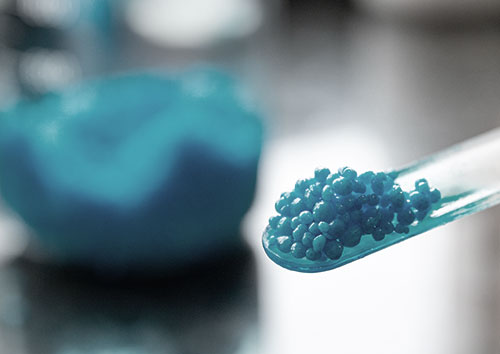

Beyonics Supplies Precision Medical Devices And High Value Product Solutions To The World’s Leading Healthcare Companies.

Operates bio-burdened clean rooms for plastics injection molding and medical devices manufacturing in a strict process and environmental control.

Provides full traceability and quality control processes.

Meets stringent safety and quality regulations.

Microfluidic chip molding.

IVD (In Vitro Diagnostic device) plastic molding and reagent filling certified to stringent medical standards.

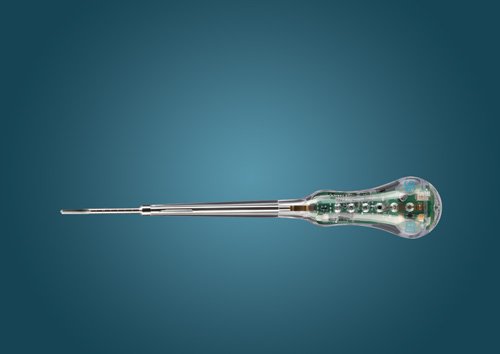

Product Example

Complex spinal surgical device

Plastics + Metal + Microelectronics + Design Engineering + Mold Fabrication + Ultrasonic Welding + Lapping + Assembly Hybrid Manufacturing

Beyonics precision manufacturing delivers innovative and mission-critical products to leading industrials.

Collaborates with leading global industrials to provide value engineering, prototyping and test development, through to full box build assembly and fulfilment.

Full traceability from component level to full products.

Flexible production systems to cater for both low mix/high volume and high mix/low volume products.

Highly responsive supply chain management.

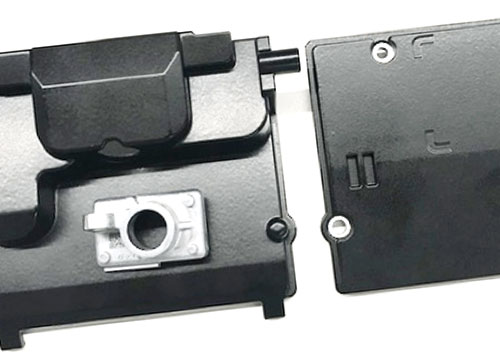

Product Example

Smart Security

Mold Design & Fabrication + Plastics + Metals + PCBA + Precision Assembly

Download Our Brochure

Get in Touch

Through a unique combination of engineering, construction and design disciplines and expertise.