CNC Machining & Precision Machining Services

Beyonics leverages advanced CNC machining and turning centers to deliver precision manufacturing solutions. Our capabilities extend to complex secondary operations across diverse materials including aluminum, magnesium, brass, and stainless steel—and the production of high-precision toolroom components such as molds, inserts, and fixtures. This integrated approach ensures optimized cycle times, unwavering quality, and on-schedule project launches for our clients.

CNC Machining & Precision Machining Services

Beyonics leverages advanced CNC machining and turning centers to deliver precision manufacturing solutions. Our capabilities extend to complex secondary operations across diverse materials including aluminum, magnesium, brass, and stainless steel—and the production of high-precision toolroom components such as molds, inserts, and fixtures. This integrated approach ensures optimized cycle times, unwavering quality, and on-schedule project launches for our clients.

Beyonics CNC machining in Singapore and our CNC machining in Malaysia and China provide high-efficiency production capacity with quality controls.

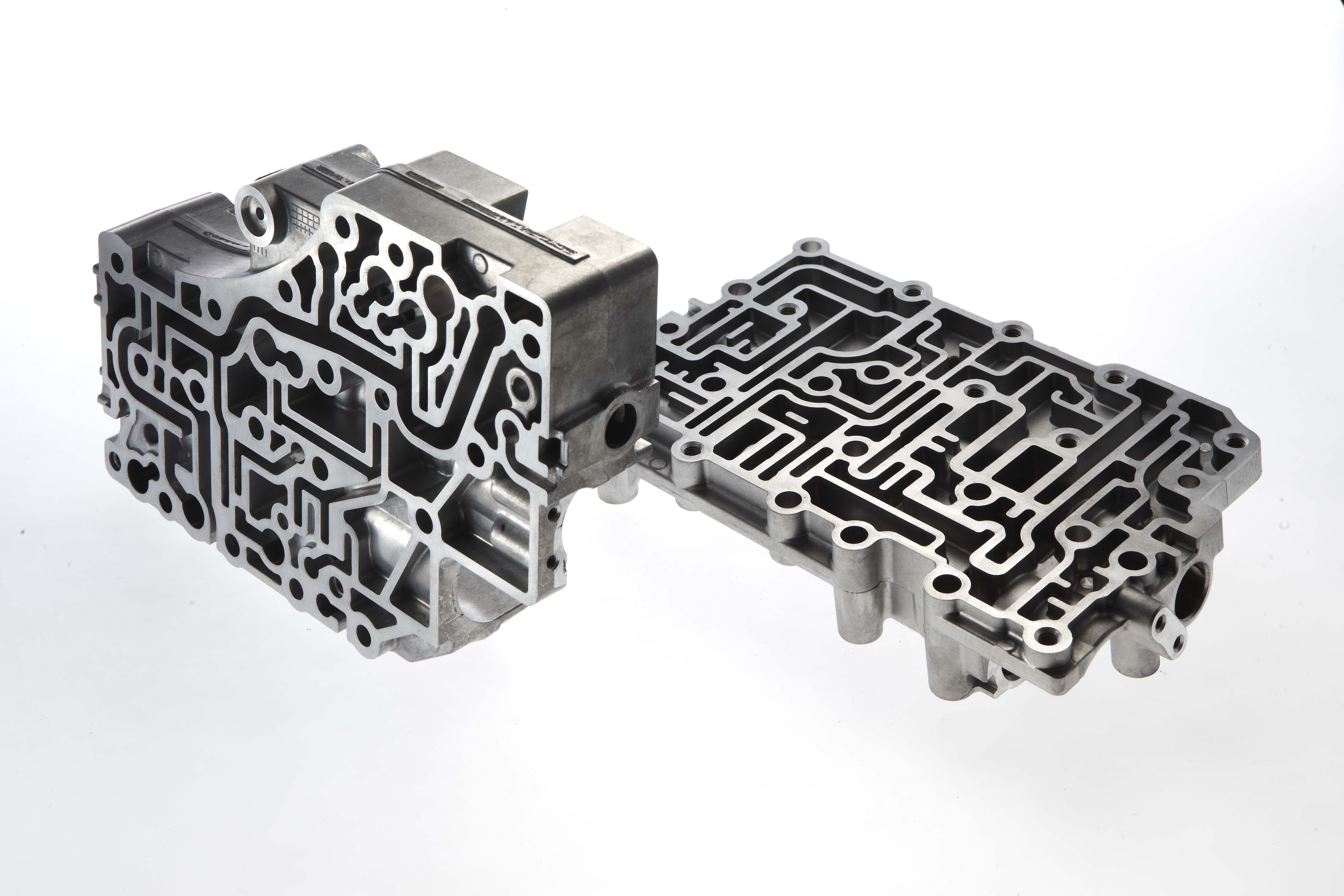

- Post casting machining of critical datums, sealing faces, bores, threads, and positional features to ensure functional accuracy and assembly readiness.

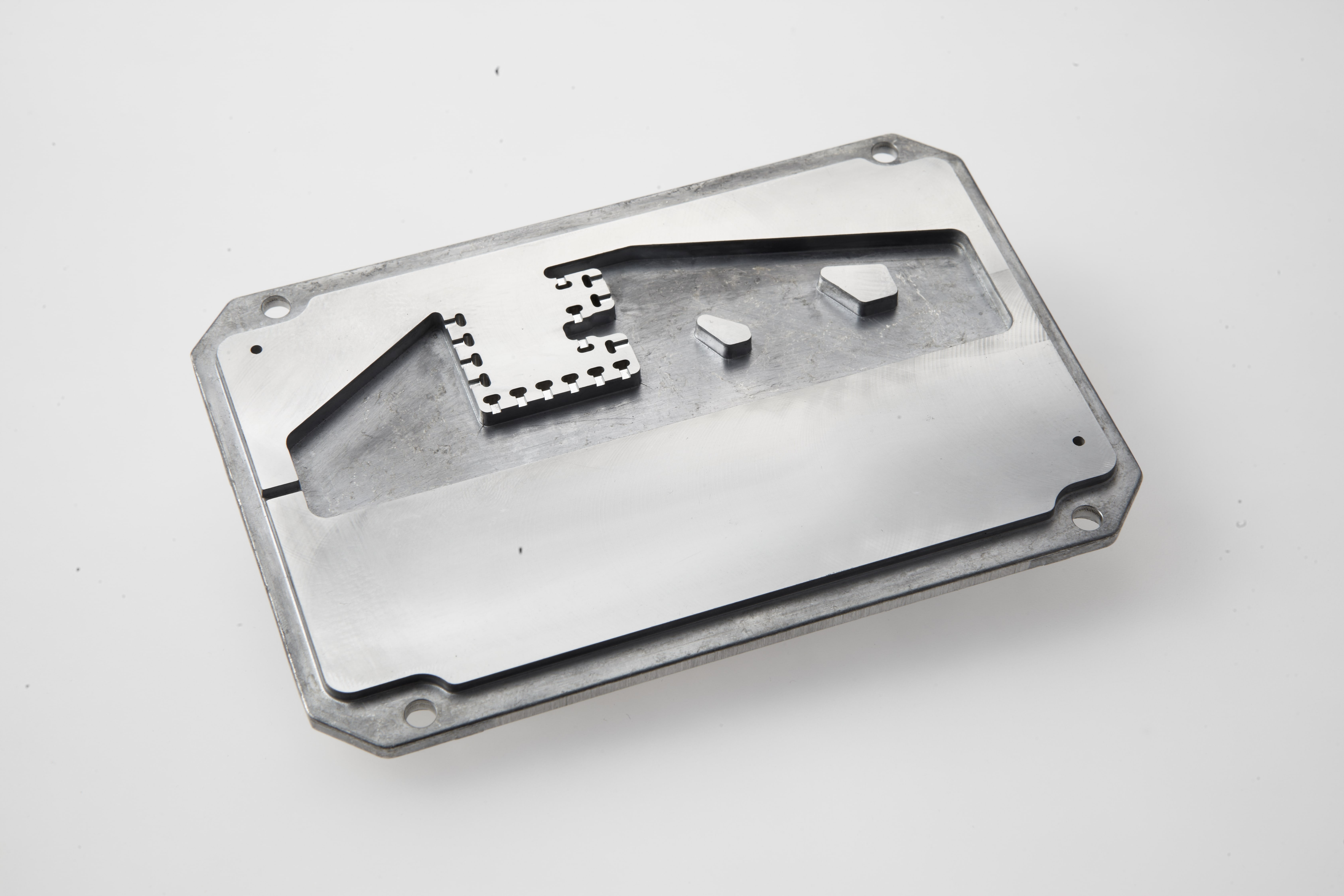

- Toolroom fabrication for precision inserts, cores and cavities, copper and graphite electrodes, and dedicated fixtures.

- Engineering continuity from prototyping through SOP, enabling scalable deployment of fixtures, cutting tools, and NC programs.

Key Offerings

- Advanced multi-axis CNC machining, including high-speed milling and hybrid systems.

- Capable of position tolerance accuracy of 8 microns and position repeatability of 4 microns

- Able to machine virtually all types of rigid materials (e.g. aluminium, magnesium, brass, stainless steel)

- Custom finishing

- Cost-effective machining for highly complex and intricate precision parts

- Precision machining to support die casting solutions

Through a unique combination of engineering, and construction

Precision Engineering Services

- Small Batch Manufacturing / prototyping

- Manufacturing Simulation

- Dimensional Inspections

- High Precision Engineering

How Customers Benefit from Our CNC Machining Service

- One accountable owner across casting, machining, and assembly, which reduces handling and lead time.

- Stable quality supported by in-process checks, CMM verification, and clear control plans.

- Faster problem solving, as the centralized system architecture of the tools enables processing teams to collaborate effectively through shared data resources.

Capability In Brief

- High-speed 3-axis and hybrid 4-axis milling for multi-face features, plus CNC turning cells for concentricity and surface finish targets.

- CNC Machining strategies tuned for thin walls, cosmetic zones, and leak paths on complex die cast parts.

- Proven experience with aluminum, magnesium, stainless steel, and brass components used in our casting and tooling programs.

Quality And Evidence

- In-process probing and SPC on critical dimensions, first-article and periodic CMM checks.

- GR&R and capability studies where safety or function requires it.

- Operations governed by ISO 9001 and IATF 16949 for automotive, with ISO 13485 available for medical programs, and ISO 14001 and ISO 45001 for environmental and occupational health where applicable.

Where CNC Fits In Your Build Plan

Die casting programs

We finish cast features to print, manage datum schemes, protect cosmetic areas, and align machining with leak and functional tests.

Plastics tooling and inserts

We process steel components and electrodes into their final shape and record and store all data to speed up shape verification and support repeatable shaping.

Assembly readiness.

We coordinate machining schedules with casting, molding, and assembly to ensure parts meet the downstream torque, sealing, and alignment requirements.