Home » From Concept to Compliance: Why MedTech Innovators Choose Beyonics

Backed by decades of engineering expertise, in-house tooling, digital validation, and ISO Class 8 cleanroom automation, Beyonics delivers the quality, speed, and regulatory assurance MedTech companies demand.

In the fast-evolving world of medical device manufacturing, precision, quality, and speed-to-market are non-negotiable. At Beyonics, we combine decades of precision engineering experience with in-house tooling design and fabrication to deliver advanced plastic injection molding solutions tailored for the medical industry.

From concept to scaled production, Beyonics is a trusted partner for complex, high-precision medical plastic components. Our end-to-end capabilities, including in-house DFM support, tool fabrication, and automated cleanroom molding and assembly, help medical device companies mitigate development risks and accelerate their path to market.

Recognized Excellence in MedTech Manufacturing

Beyonics has been nominated as a key supplier and manufacturer in the MedTech Manufacturing in Singapore: A Commitment to Engineering Excellence Directory, launched by Singapore’s Ministry of Trade and Industry. This recognition highlights Beyonics’ proven capabilities and commitment to delivering high-value medical devices and life-saving solutions to global markets.

As part of Singapore’s robust supplier ecosystem, Beyonics plays a critical role in driving innovation, supporting scalability, and maintaining stringent quality standards for the MedTech sector.

Strategic Location for Global Supply Chain Advantage

Headquartered in Singapore, Beyonics operates in a region known for its world-class infrastructure, political stability, and robust regulatory ecosystem. Our presence in Southeast Asia provides MedTech customers with access to a skilled workforce, leading healthcare markets, and efficient global logistics. This strategic footprint enables us to deliver responsive, cost-effective, and scalable solutions — helping customers accelerate product launches and manage supply chain risks with confidence.

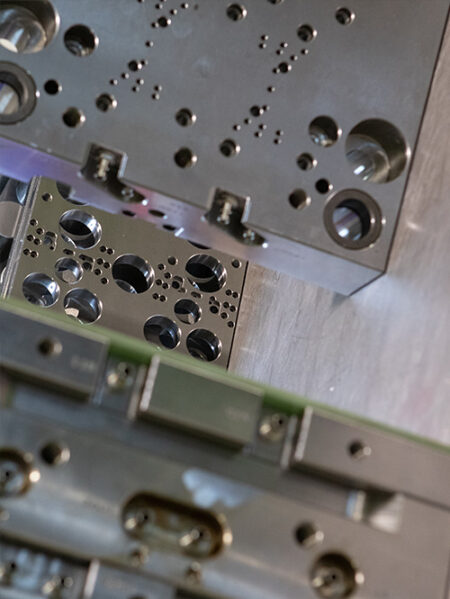

Integrated Tooling Design & Fabrication & Digital Validation

At Beyonics, our integrated tooling capabilities combine expert design, precision fabrication, and advanced digital validation within a secure, controlled environment. From the earliest stages of product development, our R&D team collaborates closely with customers to optimize designs for manufacturability, and performance. This early engagement ensures that every tool is precision-engineered to deliver consistent, high-quality part production, reducing lead times and improving overall efficiency.

We use computerized simulation techniques for mold flow analysis, part geometry, and prototype tools to prediction to minimize risk and accelerate timeline. By validating and refining tooling designs before cutting steel, we enhance first-pass yield and reduce iteration cycles. The result? Reliable, high-performance tools and a faster time to market.

High-Precision Injection Molding in FDA-Registered Cleanrooms

Beyonics delivers advanced injection molding solutions for critical medical devices, combining high-cavitation, multi-material, and micro-molding expertise with stringent cleanroom manufacturing. Our capabilities support the production of medical and diagnostic devices, as well as pharmaceutical and consumer health products — all meeting the most rigorous industry standards.

Operating in FDA-registered (Certified Reg. No: 3003080184) and ISO Class 8 cleanrooms, we ensure bioburden-controlled production for plastic injection molding, 2K molding, and automated assembly. This tightly controlled environment, paired with precision molding and high-speed automation, guarantees consistent quality and full compliance for mission-critical healthcare applications.

From Early Design to Final Delivery—We’ve Got You Covered

By integrating design, engineering, manufacturing, and maintenance under one roof, Beyonics delivers a strategic advantage—particularly for MedTech innovators. Our precision plastic injection molding and end-to-end tooling solutions help customers bring safe, effective, and innovative medical devices to market faster. Focused on reliability, scalability, and performance, we transform complex ideas into real-world solutions.

A trusted partner for MedTech manufacturing solutions

Beyonics partners with MedTech innovators through every stage – from concept to commercialization, delivering quality, speed, and regulatory compliances. Leveraging decades of technical expertise, design capabilities, in-house tooling, medical validation, and high-speed automation, we ensure efficient and reliable product realization.