Aluminium Die Casting Services

Four decades of high pressure aluminium die casting and machining knowhow

Utilizing tooling techniques and machining know-how, Beyonics offers robust end-to-end high pressure aluminium die casting solutions for the healthcare, automotive and advanced technology sectors.

Beyonics specializes in providing high-quality CNC machining services. This includes milling, turning, EDM, wire EDM, surface grinding, and finishing such as powder coating, for highly complex and intricate products. The CNC machining capability supports Beyonics’ strong die casting solutions.

Certified to IATF 16949 and ISO 9001, Beyonics has four decades of experienced professionals in PPAP and APQP, providing early customer involvement from mold flow analysis, DFM, VAVE, FMEA through die cast mold design, fabrication test and commission for mass production.

Applications

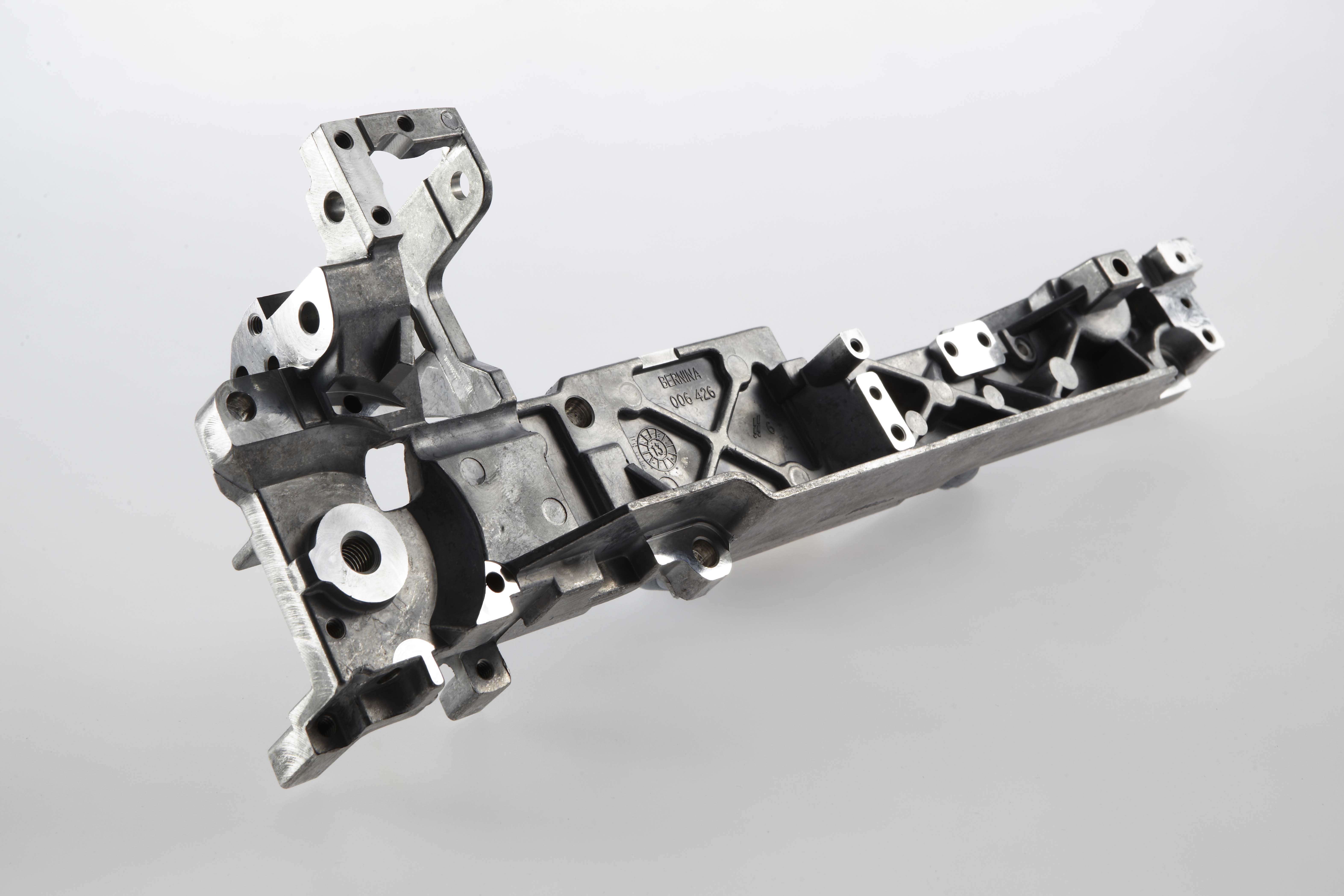

- Housings for ADAS applications such as camera, radar and laser systems with compliance to VDA 19 cleanliness standards.

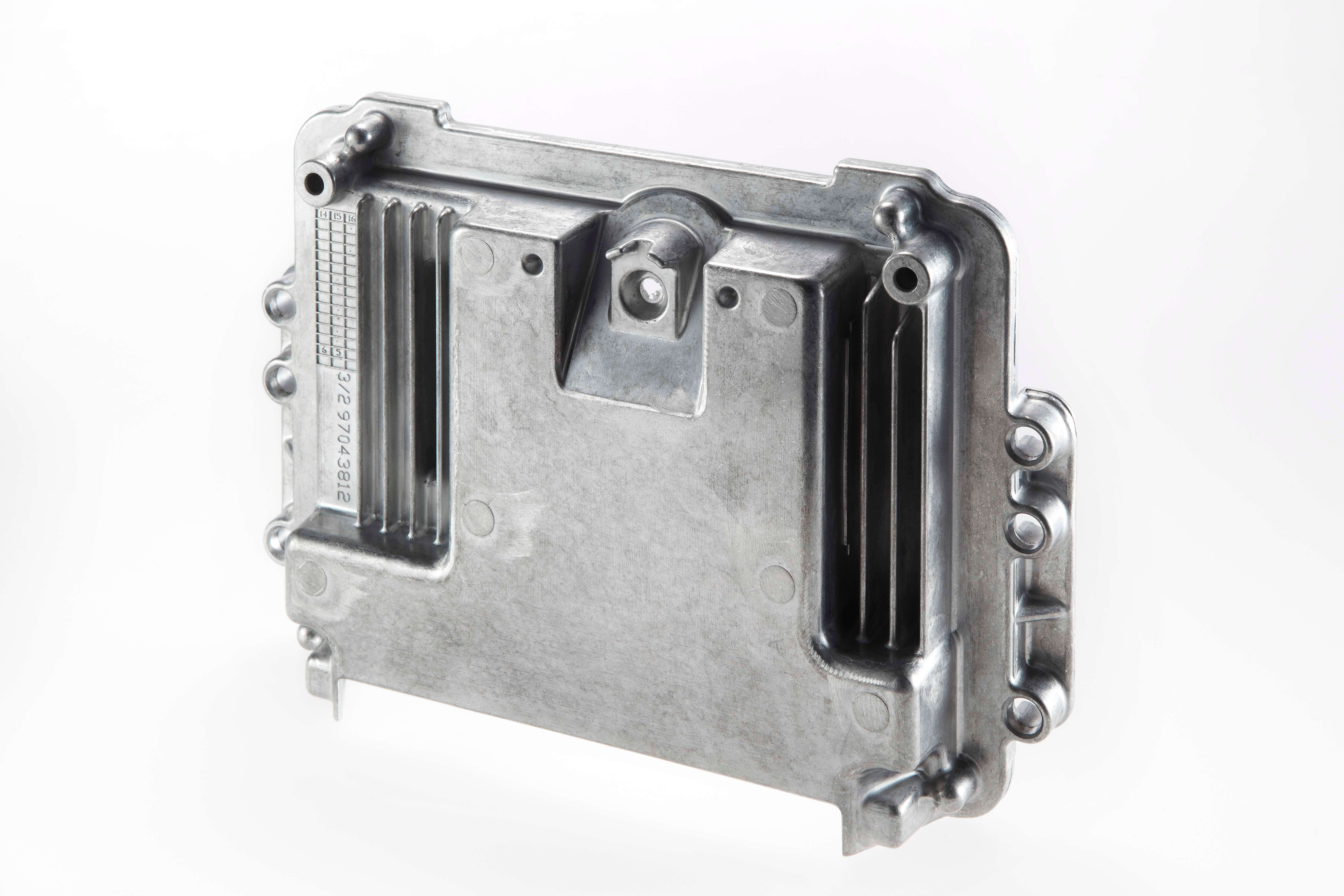

- ECU housings with good cleanliness and finishing to VDA 19 as per international standard.

- Compliance with robotic requirements through automatic deburring and porosity control refer to the NADCA.

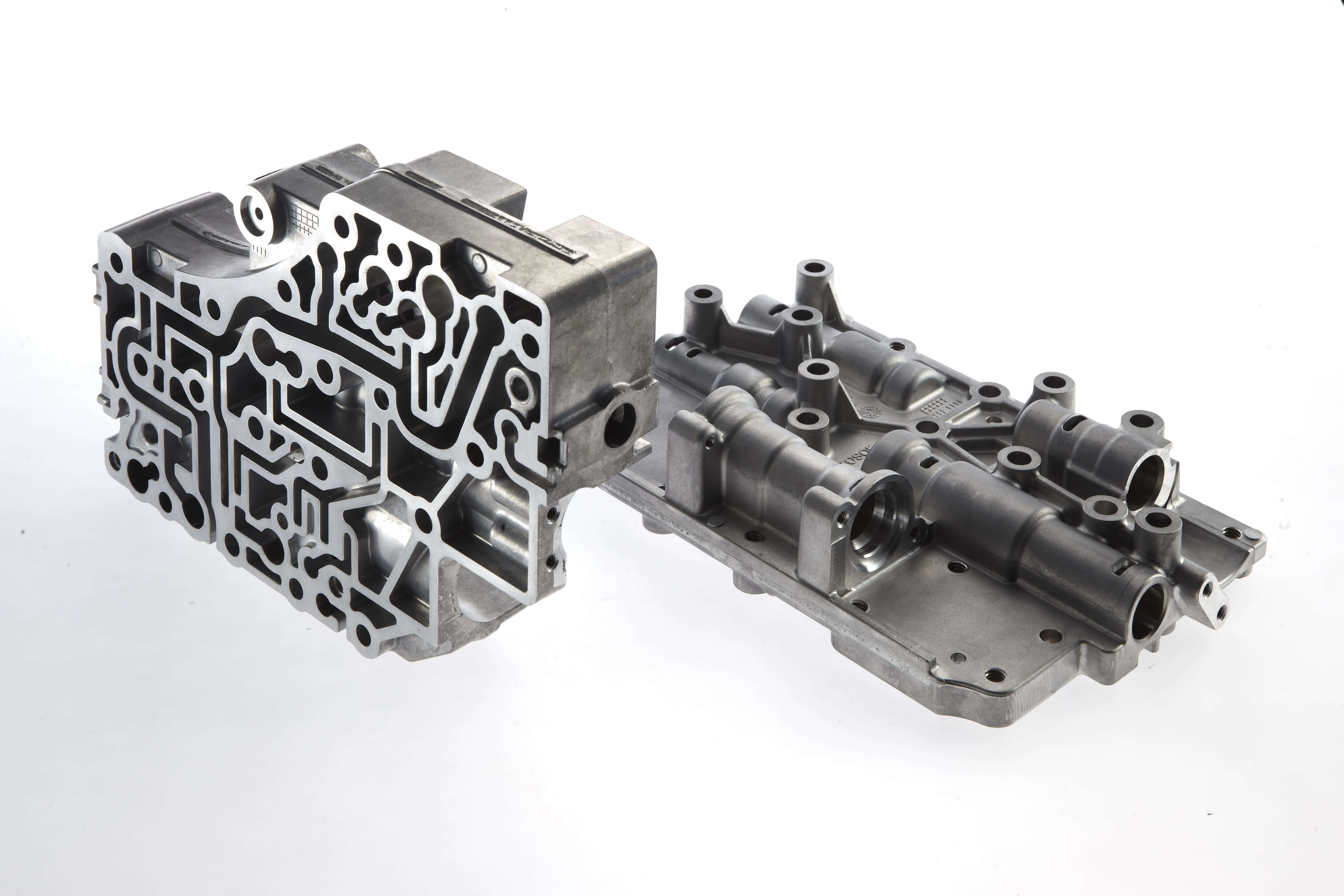

- Transmission valves from aluminium die casting and machining with leakage test development and 100% leak test capability.

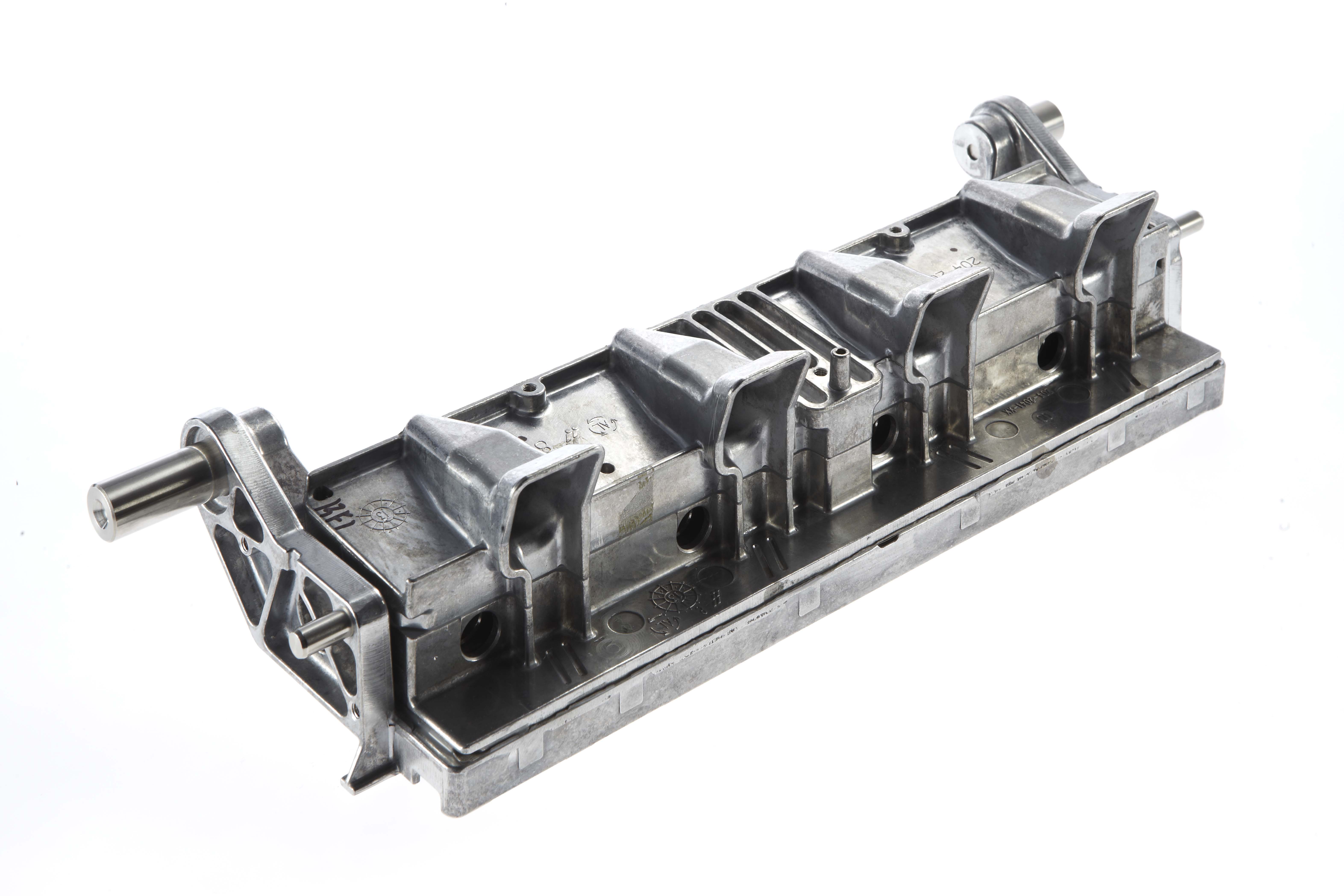

- Light weighting applications for electrical vehicles, such as housings for battery components and housings for ADAS modules.

- Thin wall applications by optimizing mold design and fabrication.

- Various material capabilities with multiple machines and furnaces.

- Strong know-how to relate to the product, tool design, process optimization, etc.

From Prototype to Scaled Production

Beyonics supports the full lifecycle of precision metal components — from early prototyping to mass production. Our aluminium die casting capabilities are ideal for complex geometries, thin walls, and tight tolerances. We deliver consistent part quality control with fast turnaround times and low cycle costs. Thanks to our vertically integrated operations, we streamline tooling, simulation, and production under one roof. Our die casting facilities in Malaysia and China are optimized for regional and international programs. This enables us to provide responsive customer support, expedited delivery, and enhanced control over quality.

Sustainability and Environmental Benefits

Our die casting process emphasizes environmental responsibility. Aluminium & metal components can be recycled indefinitely without losing its quality and performance, contributing to a more sustainable manufacturing cycle. We continually refine our manufacturing processes to reduce material waste, bring down energy consumption, and improve resource efficiency all while meeting market demand for greener solutions. By adopting modern casting techniques and embracing automation, Beyonics reduces emissions and minimizes the use of volatile organic compounds (VOCs) in surface finishing and coating stages.

Through a unique combination of engineering, design and manufacturing

Engineering

Services

We offer a complete portfolio of engineering services that enable rapid development and long-term success. Every service is designed to reduce project risk and accelerate time-to-market.

- Rapid Prototyping

- 3D Visualization of Solidification Results

- Validation Assembly of New Mold Designs

- Die Casting Process Simulation

- Tooling Design

- Manufacturing Simulation

- Metallurgical Testing

- Dimensional Inspections

- Design for Manufacturing (DFM)

Machine

Type

Beyonics operates an advanced technology fleet of die casting machines and finishing systems. We tailor our tooling and high pressure selection based on the complexity, tolerance, and volume of each part, ensuring optimized cycle times and material efficiency.

- 125 -850 ton of high pressure die cast machines

- Automatic deburring and tumbling systems

- 3-axis and 4-axis CNC machines

Quality

Control

Our quality assurance processes are designed to exceed industry standards and deliver peace of mind. Every product is verified before it leaves our facility, reducing scrap, warranty claims, and post-production costs.

- Quality Assurance laboratory with full-fledged equipment such as smartscope, CMM, Spectrometer, X-Ray Scanner and different testers

- Full test lab that diagnose cleanliness, contamination of processes, parts and systems

- Strong FOT performance. >80% of CTF dimensions within specifications

More Than Just Casting Services

Die casting is just one step in our comprehensive manufacturing process. At Beyonics, we deliver ready-to-use parts through integrated services including automated deburring, CNC machining, leak testing, CNC machining, powder coating, and assembly

By eliminating the need for multiple vendors, we minimize lead times, reduce costs, and ensure full traceability. Whether you need functional housings or cosmetic covers, we finish every part to meet both performance and appearance standards.

We serve a diverse range of industries from our ISO-certified factories in Malaysia and China, enabling our clients to stay competitive and agile.

Why Leading Brands Choose Beyonics

Beyonics is a trusted partner for companies seeking precision, scalability, and technical excellence in aluminium die casting. Here’s why:

We work closely with your engineering and supply chain teams to ensure product performance, compliance, and timely delivery from first article to serial order production shipment.

- Technical Depth: Over 40 years of experience in metal casting, tooling design, and process simulation

- Cross-Industry Expertise: Proven solutions for automotive, healthcare, and high-tech applications

- End-to-End Services: In-house tooling, machining, finishing, inspection, and assembly

- Certifications: ISO 9001, ISO 14001, ISO 45001, ISO 13485, IATF 16949, C-TPAT Compliance

- Advanced Technology Equipment: High pressure die casting (HPDC) machines, CMMs, X-ray scanners, spectrometers, melt flow index machine, instron machine, and smart inspection tools

- Global Delivery Capability: Strategic manufacturing hubs in Malaysia and China supporting regional and international projects

Let’s Talk About Your Next Project

If you need a trusted partner for high-quality parts, scalable aluminium die casting, Beyonics is ready to help. Our team supports every stage of your project from component design and simulation to casting, finishing, and delivery.

Our modern high pressure aluminium die casting Malaysia hub are strategically positioned to support regional and global production needs, with streamlined logistics and customer satisfaction service tailored to your schedule and standards.

Whether you’re developing a new product or optimizing existing parts, we offer the expertise, advanced technology, and reliability you need to move forward with confidence.

Contact us today to discuss your next die casting project or to request a quote.