Home » Precision Tooling: Where Engineering Expertise Meets Manufacturing Reality

In today’s high-tech manufacturing landscape—where medical devices require flawless reliability, electric vehicles push performance boundaries, and smart technologies demand microscopic precision—Beyonics stands as a trusted partner. Our precision metal tooling, including precision metal stamping, and plastic tooling solutions bridge the gap between ambitious designs and production reality, highlighting our precise tooling capabilities, from high-tolerance stamping dies for critical metal components to multi-cavity injection molds for complex plastic parts. Combining cutting-edge technology with decades of engineering expertise, we deliver tooling that performs across industries.

Precision Tooling Technical Capabilities That Set Us Apart

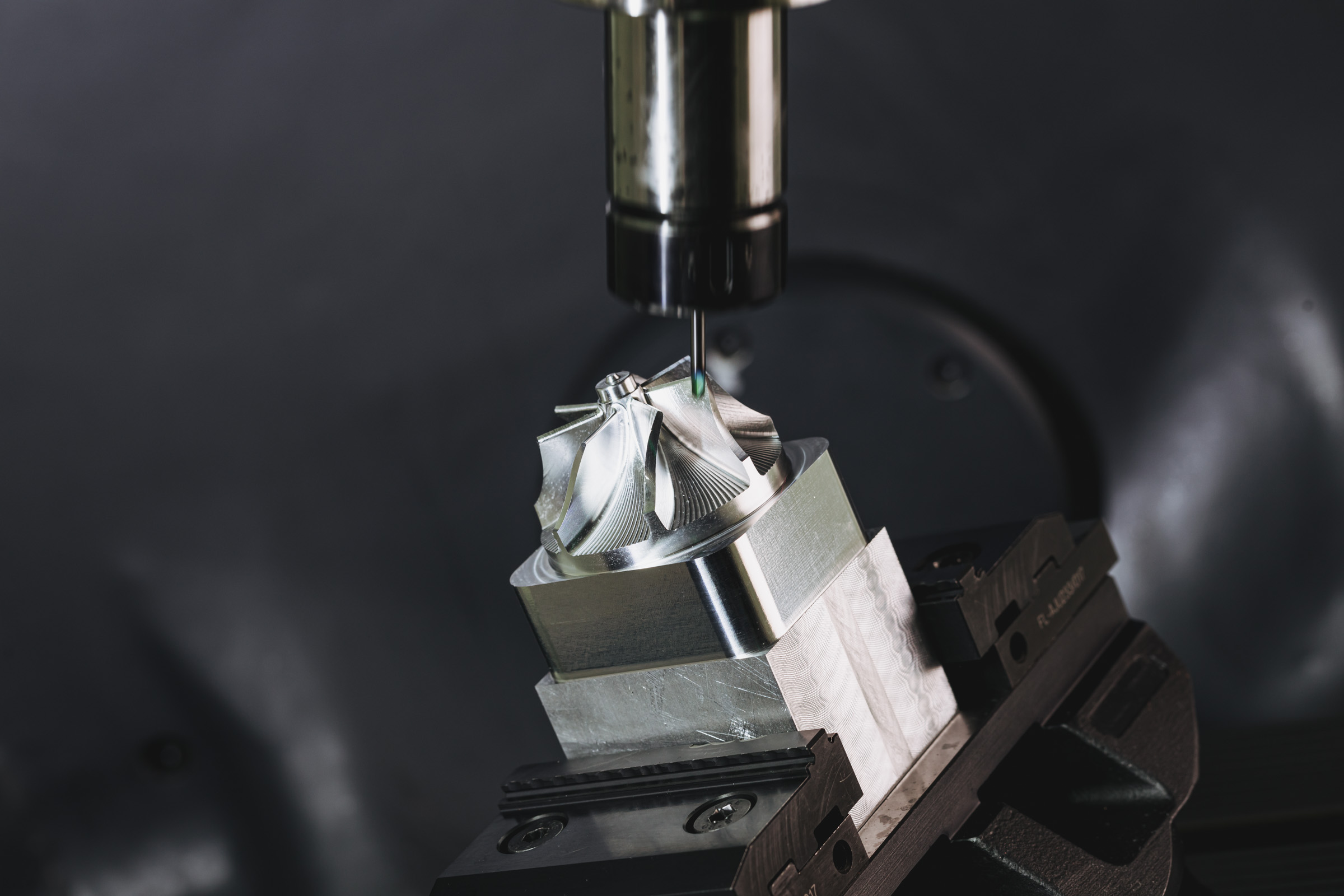

Beyonics’ tooling division operates at the forefront of precision manufacturing. Certified to IATF 16949, ISO 13485, ISO 9001 and 14001, we utilize advanced 5-axis CNC machines capable of achieving remarkable 0,005 mm tolerances, critical for medical and optical components, demonstrating our precise tooling capabilities.

We deliver precision-engineered molds ranging from micro-scale applications to complex multi-cavity tooling, consistently maintaining tight tolerances and part quality even in high-cavity production configurations.

What truly differentiates our approach is the integration of scientific molding principles with advanced simulation tools. Through Moldflow analysis, we can predict and eliminate potential manufacturing issues during the design phase, significantly reducing development time and costs. This proactive engineering approach delivers significant cost savings for customers through design optimization.

Engineering Expertise Behind Precision

Our team of senior tooling engineers, with an average of 15 years of experience, brings exceptional technical expertise and craftsmanship to every mold we produce, ensuring precision metal stamping and tooling meet the highest industry standards.

This expertise translates into tangible benefits:

Design Optimization

We've successfully reduced wall thicknesses to 0.15mm for lightweight automotive components while maintaining structural integrity.

Material Innovation

Our experience with high-performance materials like PEEK, LCP and PPS up to 60% fillers ensures optimal material selection for each application.

Process Control

Advanced in-process metrology systems provide real-time verification during machining operations.

Industry-Proven Tooling Solutions

For MedTech, Cleanroom-compatible tooling for – diagnostic and consumables. Our cleanroom molding capabilities support production of Class 8 environment components.

In Mobility applications, our tooling enables thin-wall molding solutions that contribute to vehicle lightweighting.

Smart Technology partners benefit from our precision molds for micro-connectors with <5μm pin positioning accuracy and LDS-compatible systems for integrated antenna solutions. Our optical tooling achieves all SPI standard surface accuracy for demanding applications.

Proven Track Record

Beyonics’ engineering process achieves a 90% first-time-right success rate for new tooling projects, reducing iterations and accelerating production timelines.

Our global support network provides 24/7 engineering assistance across manufacturing sites, ensuring continuous production uptime and consistent quality in precision metal stamping operations.

At Beyonics, we maintain a rigorous validation process for every tool—from precision metal stamping dies to complex plastic injection molds—guiding each project from concept to production. Our engineering team conducts extensive trials and sampling runs to verify dimensional accuracy and functional performance across both metal and plastic tooling systems before approving full-scale manufacturing. Through process optimization informed by real production data, we deliver consistent quality output. This disciplined approach, backed by proactive tooling maintenance programs, ensures sustained performance throughout the product lifecycle without compromising reliability.

Contact our engineering team to discuss your specific requirements.

With decades of experience serving MedTech, Mobility, and SmartTech leaders, our methodology meets the exacting standards of modern manufacturing. Partner with Beyonics to leverage our metal and plastic tooling expertise for your next innovation.