Solutions d'outillage en plastique

Innovative design and precision tooling solutions for aluminum die casting and plastic injection molding projects

Les outilleurs expérimentés de Beyonics sont spécialisés dans la fourniture de solutions d'outillage créatives pour soutenir les projets de moulage sous pression de l'aluminium et les processus de production de moulage par injection des matières plastiques.

Applications

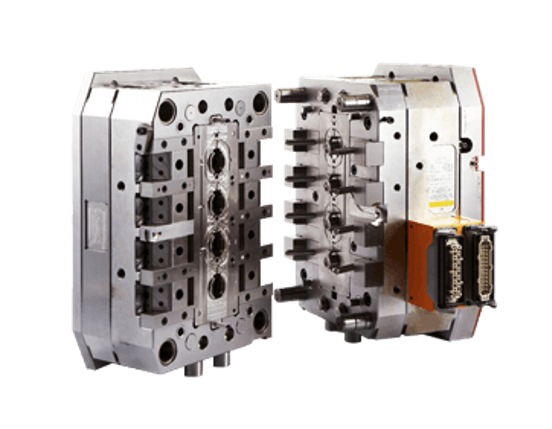

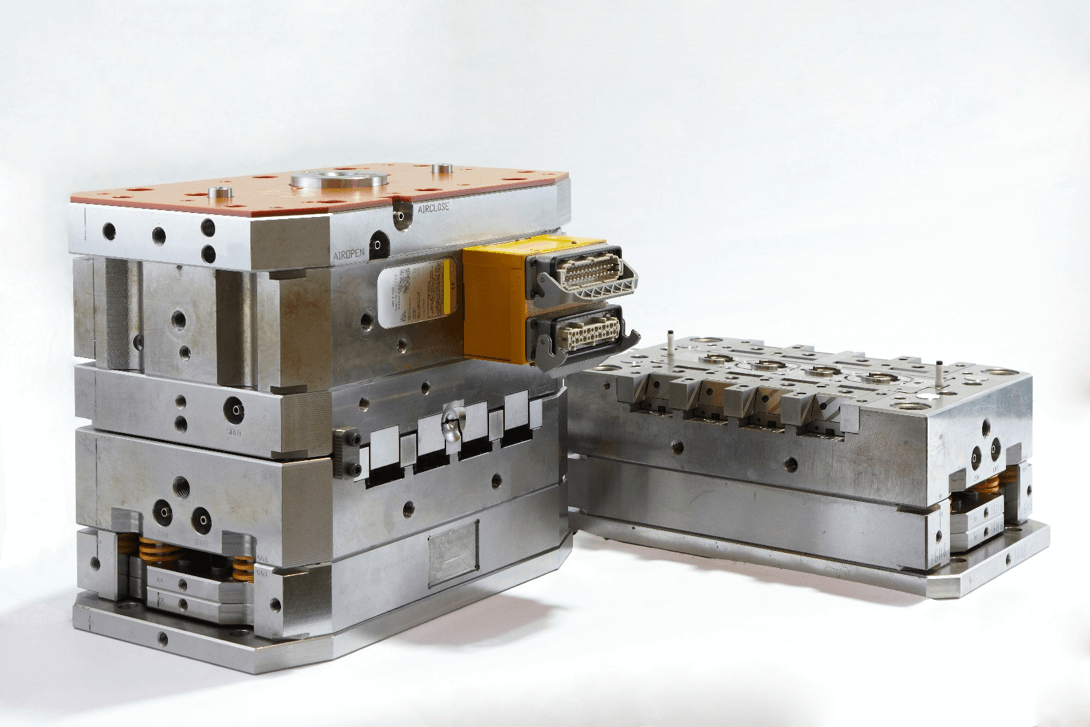

- Multi cavity molds up to 64 cavities

- Double color injection molding (2k)

- Unscrew molds

- Insert molding / Over molding

- Moules pour petites pièces de précision à grandes pièces de 15 à 1600 tonnes.

- Pièces dont l'épaisseur de la paroi est inférieure à 0,18 mm.

Grâce à une combinaison unique d'ingénierie et de construction

Ingénierie

Services

- Conception pour la fabrication (DFM)

- Implication précoce

- Analyse de l'écoulement des moules

- Automatisation sur mesure

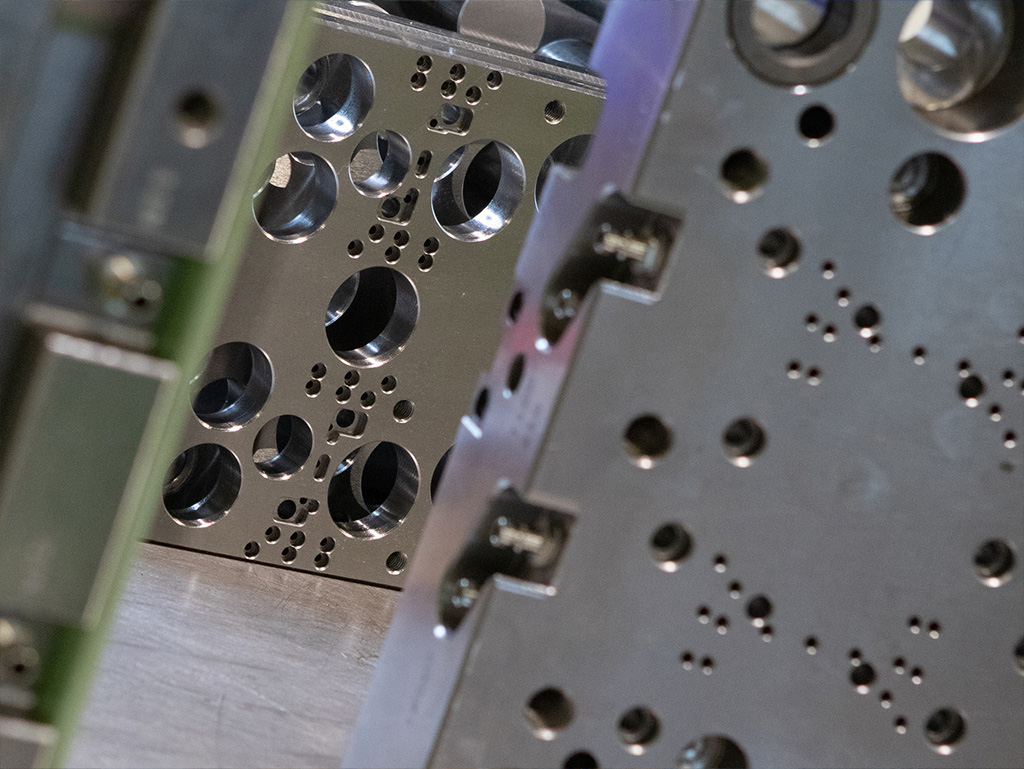

Precision CNC Machines

- 3 Axis CNC Milling | Makino, DMG, Roders, Fanuc

- 5 Axis CNC milling | DMG

- EDM | Makino, Sodick, Charmilles

- Wire EDM | Makino, Sodick, Charmilles

- 5axis & 3 axis CMM | Smart scope | Digital microscope

- Software | Siemens NX | Moldflow | Solid works | Novacast

Qualité

Assurance

- ISO 9001

- ISO 14001

- ISO 13485

- IATF 16949

Why Customers Choose Beyonics

At Beyonics, we integrate design, simulation, machining, and metrology to minimize risk and accelerate project timelines. The result is higher yield, stable cycle times, and fewer cosmetic issues in mass production. This is the value clients expect from plastics tooling built by experienced engineers and toolmakers.

What you gain

- Early DFM that protects function while simplifying steel.

- Moldflow insights that guide gate type, venting, and cooling layout.

- Clean tool build using proven EDM, 5-axis milling, and precision grinding.

- Reliable tryout supported by in-house CMM and optical inspection.

- Clear documentation, change control, and traceability.

Our Approach to Plastic Tooling Manufacturing

Strong results come from a structured process. We keep it simple and transparent.

- Feasibility and DFM – we review models, highlight risk features, and propose steel-safe strategies.

- Review of the CAD file – highlight risks and provide proposal to improve manufacturability

- Mold flow analysis – to predict potential molding defects like warpgae, airtrap, short moulding etc and provide proposals to customer

- Build and Metrology – Electrodes and steel are verified before assembly, which speeds tryout. Inserts are measured and comply with drawings specification before mold assembly and trial

- Established process optimization procedure – to ensure consistent quality, efficiency, and reliability in production

- Handover and Support – You receive drawings, BOM, spares, and maintenance schedules for sustained uptime.Mold license file with complete mold history will be provided during mold transfer

Validation and Quality Evidence

Regulated programs require proof. Our teams prepare first-article reports, capability checks on critical dimensions, and GR&R where needed. ISO 9001, ISO 13485, ISO 14001 and IATF 16949 systems support consistent documentation and audits.

Lifecycle and Maintenance Support

Established maintenance and spare management strategy to support production during the guaranteed life time of each molds

Regional Advantage for Plastics Tooling Asia

Programs often need proximity to molding, final assembly, or logistics hubs. Our Asian operations provide responsive engineering and steady capacity for plastics tooling in Asia, with common software, shared methods, and the same quality standards across sites. This helps teams dual-source tools and balance risk without retraining.

Typical Business Outcomes

- Faster qualification with fewer loops between T0 and SOP.

- Lower scrap driven by stable molds and balanced flows.

- Predictable delivery supported by standard work and reliable metrology.