Services d'assemblage de circuits imprimés (PCBA)

Prise en charge de la gestion complète de la chaîne d'approvisionnement et de la rotation rapide pour la construction de prototypes et la production de masse

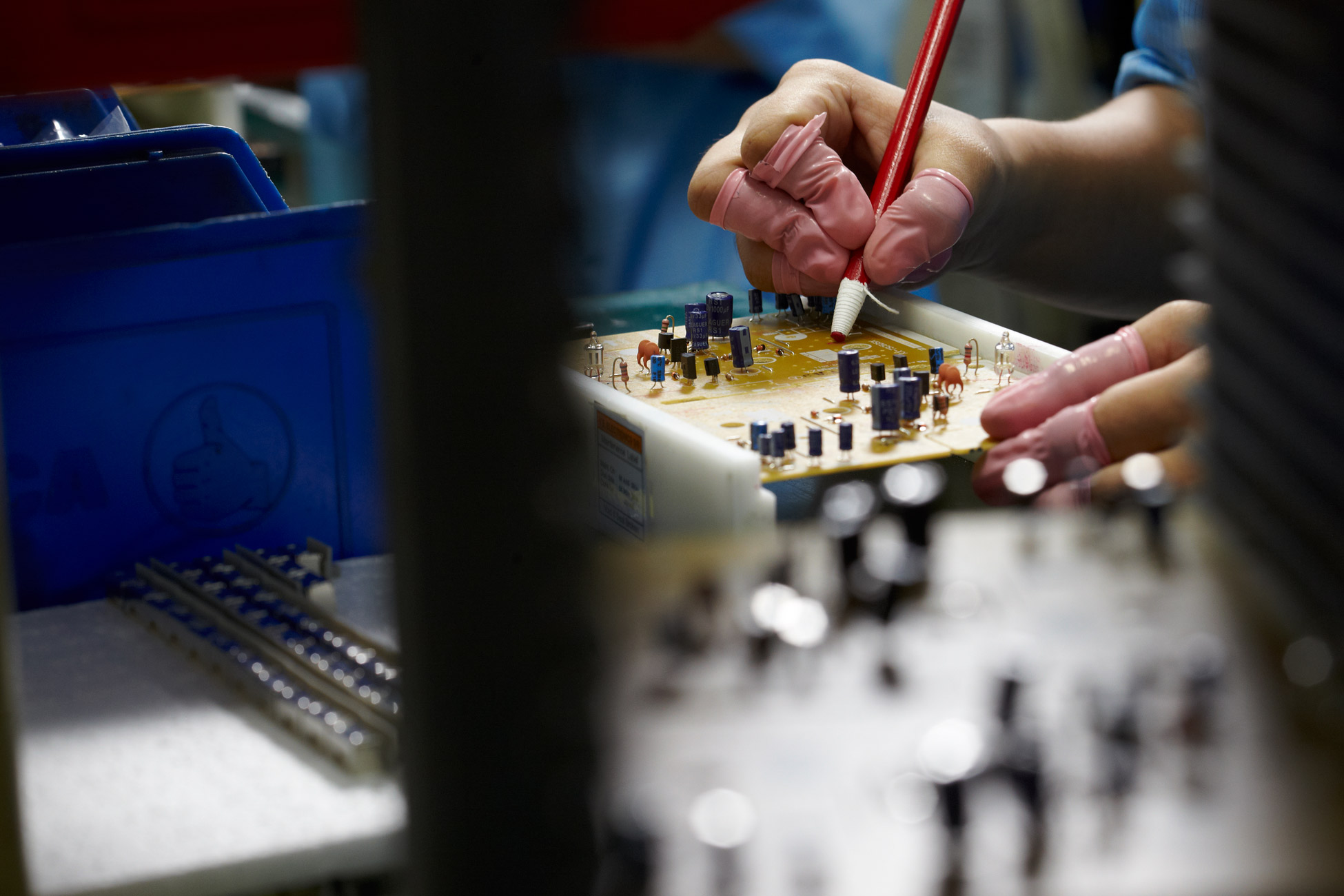

Beyonics supports complete printed circuit board and box-build assembly, and can help clients in both high mix low volume and low mix high volume productions. Leveraging our specialized manufacturing campus in Malaysia, we operate 6 high speed SMT lines to simultaneously accommodate both rapid prototype development and high-volume production demands.

Grâce à une combinaison unique d'ingénierie, de conception et de fabrication

PCBA

Processus

- Receiving & Incoming Quality Inspection & Materials Kitting

- MES – Manufacturing Execution System for traceability

- L'inspection

- Emballage

- X-Ray inspection

- Soudure à la vague

- Dépanelliser

- PCBA testing

- SMT Assembly, with 3D solder paste inspection and 3D automated optical inspection

- PTH soldering – Manual & Automated

- COB – Chip On Board capability

- Box Builds Assembly

- Functional Testing

- Conformal Coating

- Produits finis et expédition

PCBA Testing

- Test en circuit : Station de test Agilent pour la production en grande série.

- Sonde volante : Applicable à la production de faible volume à forte mixité et à la construction de NPI.

- Functional Test: Work with the customer to develop test plans and testers for functional testing.

Qualité

Assurance

Beyonics, fabricant renommé dans le domaine de l'assemblage de circuits imprimés (PCB), adhère à plusieurs certifications et normes afin de garantir le plus haut niveau de qualité et de fiabilité dans ses processus de fabrication et de validation. Ces certifications jouent un rôle crucial dans l'établissement de la crédibilité de l'entreprise et démontrent notre engagement à respecter les normes de l'industrie.

- ISO 13485 : 2016

- ISO 14001 : 2015

- ISO 45001 : 2018

- ISO 9001 : 2015

- IATF 16949 : 2016

- Assemblage électronique : IPC-A-610

- C-TPAT Custom Trade Partnership Against Terrorism (Partenariat pour le commerce douanier contre le terrorisme)

- Système de traçabilité des lots : Système de gestion de l'atelier en interne

Why Teams Choose Beyonics for PCBA

You need builds that start fast and pass inspection the first time. Our PCBA operations focus on stable processes, clear documentation, and dependable lead times. We support fast prototypes and steady volume on the same campus, so PCB assembly stays consistent as demand grows. For programs that require coordination across suppliers, we manage PCB manufacturing and assembly with audited partners and full material traceability. That keeps PCBA and manufacturing predictable from NPI to mass production.

Capabilities That Support Your Build

We combine process control with practical engineering support so your PCBA meets schedule and quality goals.

- NPI and quick-turn builds for early validation and EVT/DVT.

- Surface mount and through-hole assembly with controlled profiles and ESD protection.

- Workmanship to IPC-A-610 with training aligned to your class requirement.

- Box-build and system assembly including labeling, packaging, and finished-goods handling.

- Supply chain coordination for PCB manufacturing and assembly, including AVL adherence and lifecycle checks.

- Change control and documentation that scale from prototype to series production.

Design for Manufacturability, Assembly, and Test

Good design decisions reduce rework and time to approval. Our team reviews Gerber data, BOMs, and test coverage to improve outcomes before the first build.

- DFM to flag risk features and clarify stack-up or spacing constraints.

- DFA to reduce manual touch points in PCB assembly.

- DFT to raise coverage in PCBA

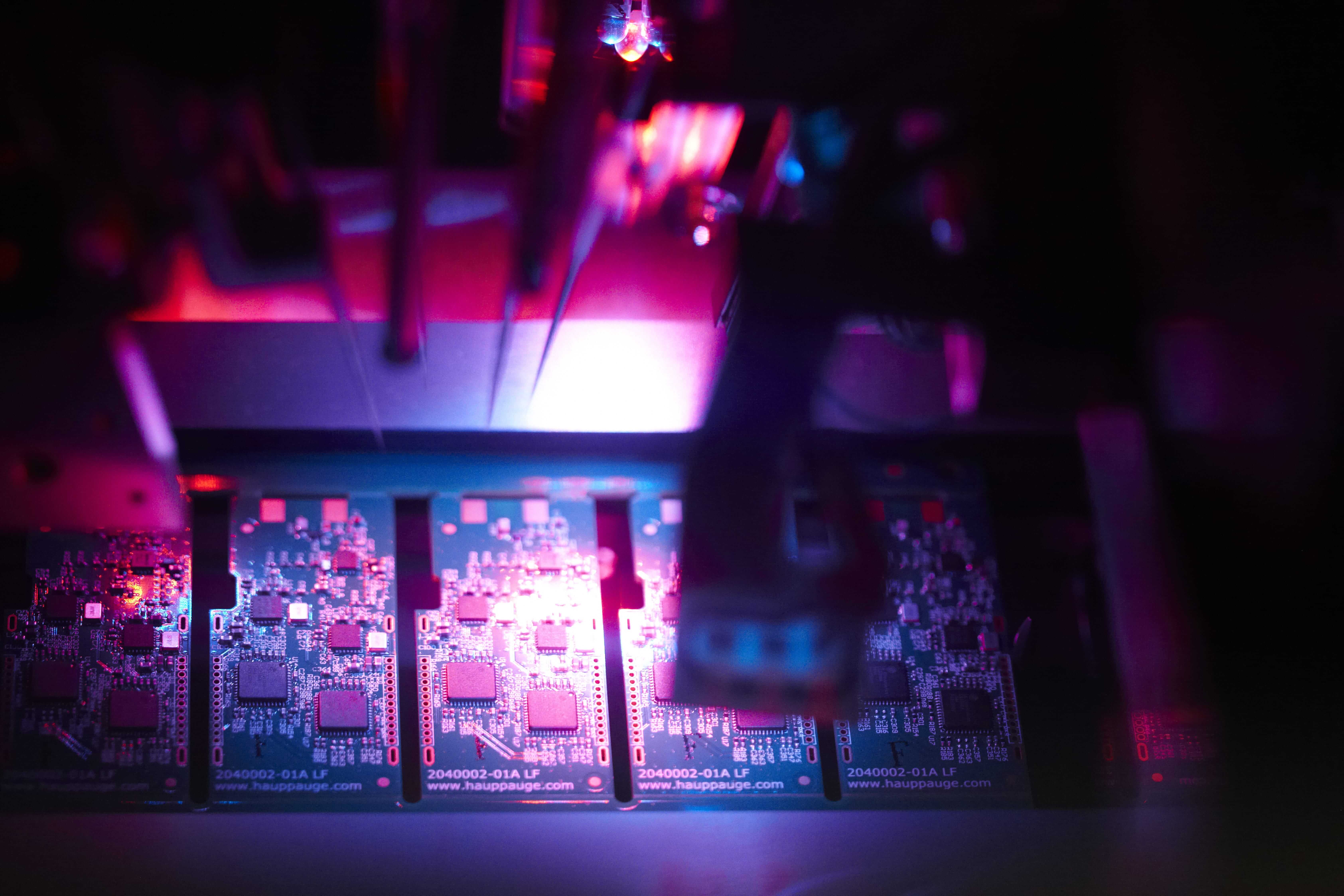

Inspection and Test Coverage

Robust inspection protects yield and field reliability. We apply a layered approach and tailor depth to program needs.

- 3D Solder paste inspection and 3D AOI for consistent print and component placement.

- X-ray inspection for hidden joints when specified by the build plan.

- In-circuit test for high-volume coverage where fixtures make sense.

- Flying probe for high-mix or early builds.

- Functional test developed with your team to validate real-world performance.

These controls shorten debug time and support clean handoffs from prototype to repeated PCBA builds.

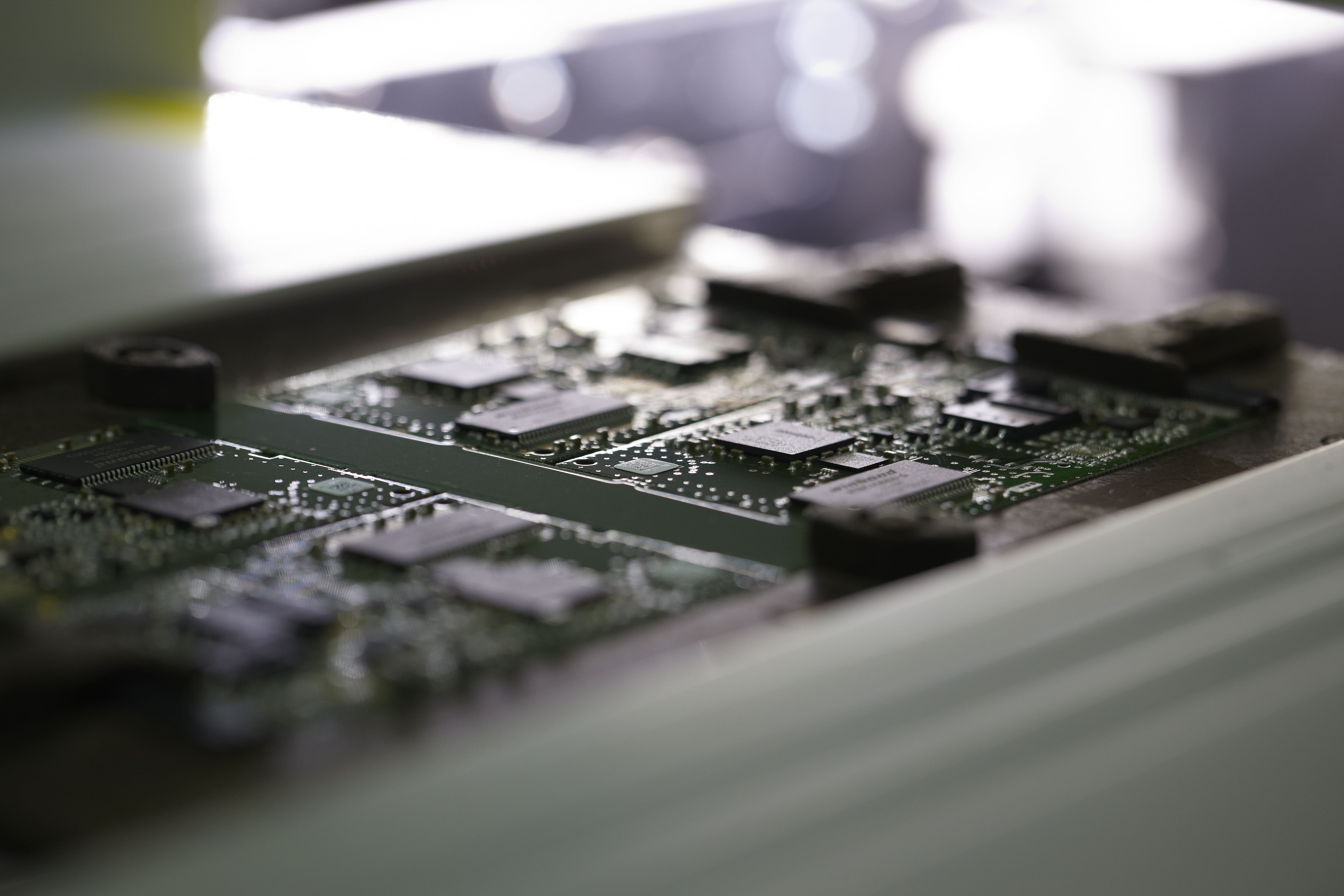

Materials, Sourcing, and Traceability

Component availability can make or break timelines. We manage AVL compliance, approved alternates, and moisture-sensitive handling. Our shop-floor system supports lot-level tracking for reels, PCBs, and finished sub-assemblies. When customers need PCB manufacturing and assembly under one plan, we coordinate bare board fabrication with qualified suppliers, then complete PCB assembly and final box-build on the same campus. This simplifies PCBA and manufacturing for multi-site programs.

Quality and Compliance

Your builds run under audited systems with consistent records. Certifications include ISO 9001, ISO 13485, ISO 14001, ISO 45001, IATF 16949, and IPC-A-610 workmanship. These standards support customer audits and regulated market requirements while keeping everyday PCBA clear and accessible.

Typical Use Cases We Support

- NPI lots that must move quickly without sacrificing evidence and traceability.

- High-mix service for spares, options, and late-stage configuration.

- Stable volume where repeatability and on-time delivery matter most.

Turnkey PCB manufacturing and assembly with managed logistics and packaging.