Home » Driving Automotive Efficiency: Cost-Effective Production through Precision Metal Stamping

In the fast-paced and ever-evolving automotive industry, efficiency, reliability, and cost-effectiveness in production are more crucial than ever. As demands for advanced and economically produced vehicles rise, the significance of adopting superior manufacturing processes cannot be overstated. Beyonics stands at the forefront of this transformation, specializing in the delivery of unparalleled precision metal stamping solutions tailored to meet the stringent demands of the automotive sector.

Transforming Production with Precision Metal Stamping

Our expertise in metal stamping, particularly our state-of-the-art deep-drawn precision techniques, is revolutionizing the production of complex metal parts. The ability to transform sheets of metal into intricate components swiftly and accurately plays a pivotal role in enhancing operational efficiency and reducing costs. At Beyonics, we take pride in our capability to achieve tight tolerance levels of +/-0.0254mm, ensuring each component meets the automotive industry’s exacting standards.

Cutting-edge Technology for Optimal Results

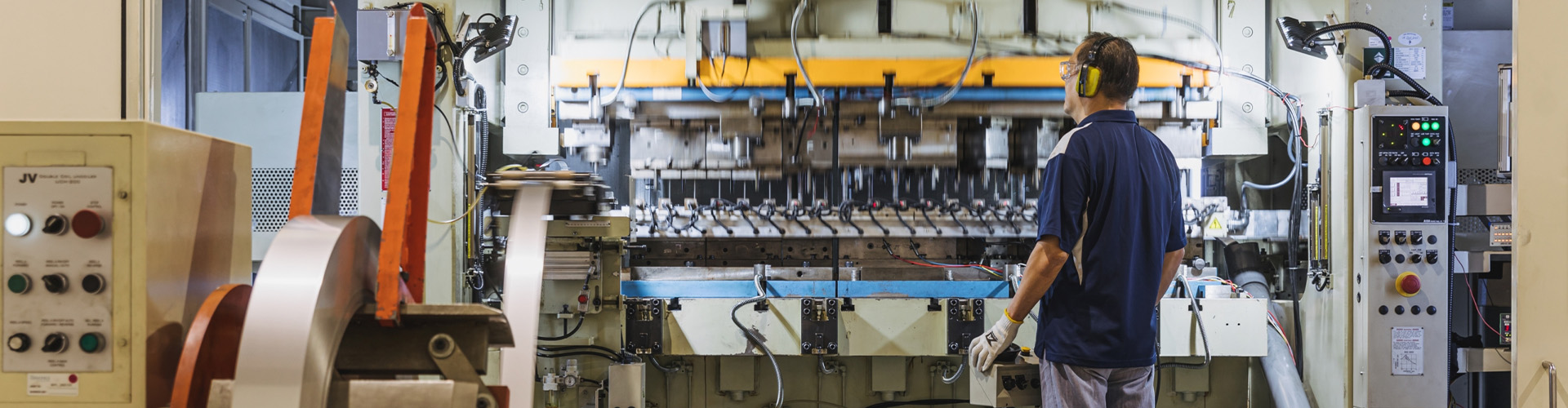

We understand that the backbone of superior metal stamping solutions lies in the technology utilized. Our precision multi-station transfer stamping machine is engineered for complex and tight-tolerance deep-draw metal stamping tasks, making it perfectly suited for manufacturing automotive sensor housings and other critical components. Coupled with our double crank-shaft precision stamping press and a 3D servo feeding system, we can accommodate modular stamping dies across extensive stages, resulting in unparalleled precision and durability for high-volume operations.

Deep-Drawn Transfer Stamping: The Future of Manufacturing

We understand that the backbone of superior metal stamping solutions lies in the technology utilized. Our precision multi-station transfer stamping machine is engineered for complex and tight-tolerance deep-draw metal stamping tasks, making it perfectly suited for manufacturing automotive sensor housings and other critical components. Coupled with our double crank-shaft precision stamping press and a 3D servo feeding system, we can accommodate modular stamping dies across extensive stages, resulting in unparalleled precision and durability for high-volume operations.

Your Partner in Driving Automotive Innovation

Beyonics is more than a solution provider. We are a partner in driving the future of automotive manufacturing. Our dedication to innovation, quality, and efficiency makes us the preferred choice for automotive industry professionals who are committed to optimizing their production processes. We invite you to explore the possibilities that our precision metal stamping solutions offer, promising not only to meet but exceed your production needs with the utmost efficiency and attention to detail.